Challenge.

Asda tasked Aura’s packaging consultancy team to help improve efficiencies of it’s automated distribution centre and eliminate re-packing of products.

The brief was to review the efficiencies of its automated distribution centre and eliminate the £1,000,000 per annum cost to business due to inefficiencies and unnecessary damage of product and packaging.

Solution.

How we helped.

Working with Asda’s distribution centre team, our team of consultants delivered:

- Full evaluation of current distribution packaging solutions, process and procedures

- Recommendations on improvements to deliver consistency and efficiency

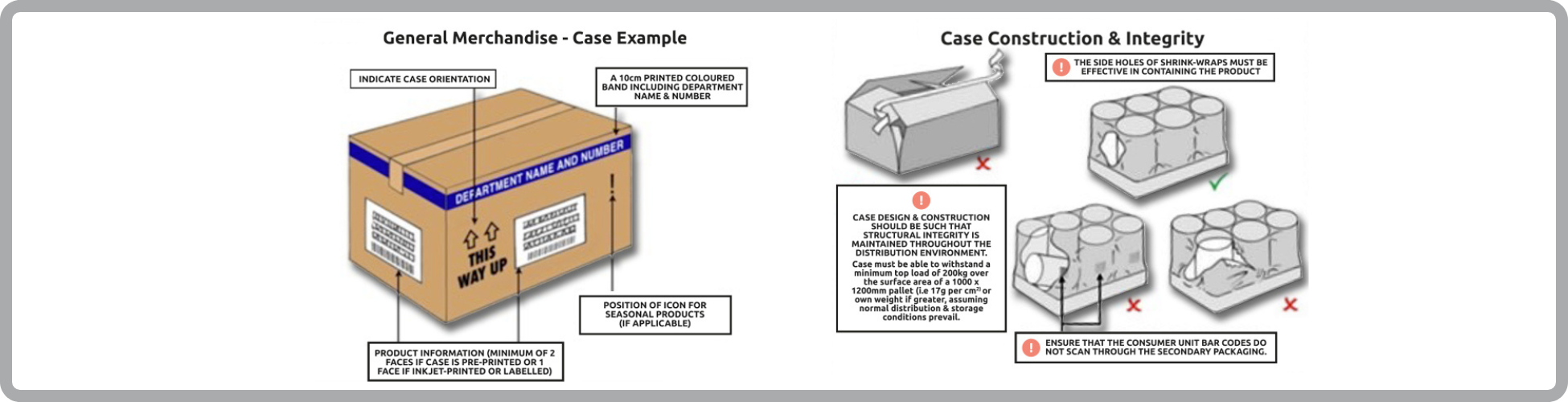

- Produced a set of pictorial guidelines for global suppliers, clearly communicating Asda’s requirements for it’s automated distribution centre

- Communicated and distributed guidelines to all suppliers and Aura also supplier suppler support to ensure understanding and a smooth transition

Benefit.

Asda eliminated the £1,000,000 per annum cost to business due to inefficiencies and additional labour costs. In addition, Asda enjoyed an annual saving of £365,000 secured through the reduction of damages and product waste. By having guidelines that helped hold its suppliers accountable, efficiency improvements were achieved across the enter distribution chain.

Impact.

Together we eliminated £1,000,000 cost to business AND generated a further £365,000 annual savings through the reduction of product and packaging waste.